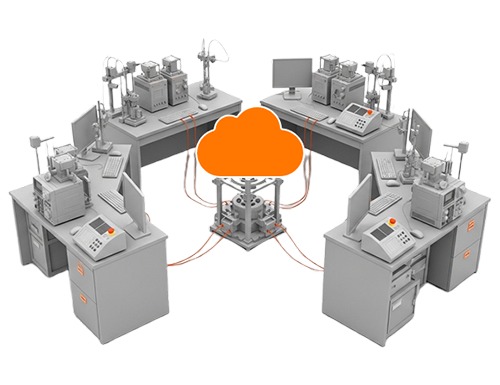

The Future of Technical Mastery. Your all-in-one Virtual Engineering Lab.

We build the labs that build the experts.

Velnode gives you the tools to train, build, and scale your technical vision in a risk-free virtual sandbox designed for the next generation of engineers & technicians.

Technical Scene, Playground & Explainer Video All in One place.

Setup takes 5 minutes!

Cross-Platform

Process Simulation Engine

The Digital Asset Bridge

Easy to Embed

Intuitive Technical Labs With Powerful Modeling & Physics Engines

-

High-Fidelity Solvers: Execute real-time multiphysics simulations & models including fluid flow, pressure, level, temperature, as well as electrical, instrumentation, mechanical and engineering equipment animations.

-

Deterministic Logic Validation: Sync virtual PLC/DCS code with physics-based feedback loops to verify control response before field commissioning.

-

Non-Linear Asset Modeling: Simulate complex equipment behaviors such as valve, pump, seperators, heat exchangers, compressor, HVAC systems and rotating mechanical equipments.

We’re Better. Here’s Why…

Designed for the field, replaces complex command and simulation workflows with a streamlined, drag-and-drop industrial devices tailored for real field technical experience.

Zero-Install Access

Launch high-performance engineering labs instantly through any standard web browser.

Collaborative Lab Spaces

Share active lab sessions with remote teams for over-the-shoulder training and real-time technical mentorship.

External Integration Hooks

Connect your lab to third-party digital twin platforms or predictive maintenance software via secure API extensions.

Lab Interface

Deploy and scale complex industrial technical labs through animated field devices built for rapid, field-accurate simulations and animations.

Playground Options

Shift high-stakes training into a deterministic sandbox, eliminating the potential for asset damage while maximizing technical proficiency.

Scene Manager

Manage and scale industrial environments using a predictable, step-by-step configuration logic that ensures consistency across all simulation models.

Industrial Devices

Render equipment motion—such as valve actuation, pump rotation, or piston displacement—driven by underlying variables like pressure, torque, and fluid velocity.

Tag Maps

Bridge the gap between virtual assets and industrial controllers using standardized industry protocols, ensuring data integrity across the entire control stack.

Simulations & Models

Deploy deterministic simulations engineered to mirror the exact mechanical, thermal, and fluid dynamics of active industrial environments.

Active Testbeds: High-Fidelity Labs for System Validation.

Engage with our high-fidelity technical environment to evaluate the full spectrum of system capabilities and industry-specific simulation possibilities.

A ligula risus auctor and justo tempus blandit

Graphic Design

Integer urna turpis donec and ipsum porta justo

UI, Interaction Design

Donec sapien augue undo integer turpis cursus

UX, Illustration

Laoreet undo magna at suscipit undo magna

Web Design

Donec sapien an augue integer turpis cursus

Web Design

Donec sapien an augue integer turpis cursus

UI, Interaction Design

80%

Deterministic Accuracy

Virtual behavior mirrors real-world field data.

99%

Physics Core

High-speed calculation of fluid, thermal, and mechanical variables.

100%

Situational Awareness

Real-time visibility into internal system states.

Stories From Our Customers

Hear from engineers & technicians who have transitioned from theories to physics-governed industry field readiness models and simulations on our platform.

Before Velnode, most of my students graduated without ever 'touching' a process control loop. By integrating Velnode’s VLaaS model, we provided students with the required capability to play around and master control loops.

We can now simulate catastrophic tank overflows and short circuits in a risk-free environment. Velnode hasn’t just replaced our testing and training equipment; it has democratized our classroom."

I couldn't afford to set up a $5000 physical PLC training kit. With Velnode monthly subscription, i have access to a world-class lab with similar functionality.

I spent weeks practicing on the Digital Twin of a three-phase separator. During my interview with an indigenous service company, I was able to explain the logic of a PID controller as if I had been working on a live rig for years

The ability to connect the software to actual PLCs via Modbus means our trainees get the most realistic experience possible without us having to own a single physical pump.

We were skeptical about 'virtual labs' because of our local internet speeds. However, Velnode’s lightweight Javascript engine worked flawlessly even on 3G connections.

Our students are now designing and testing circuit breakers and heat exchangers from their tablets. Geographical location is no longer a barrier to technical mastery for our global students.

Velnode changed our entire business model. We transitioned from a capital-heavy physical center to a lean, cloud-based technical training provider.

Everything you need to know before getting started

Does Velnode require a high-end gaming laptop to run?

No. One of Velnode’s core innovations is its lightweight 2D Vanilla JavaScript engine. It is specifically optimized to run smoothly on standard "student-grade" laptops and mobile devices, even on low-bandwidth internet connections

Do I need to install heavy software on my computer?

No. Velnode is entirely browser-based. You can access your virtual lab from any device (laptop, tablet, or desktop) with a standard web browser, eliminating the need for complex installations.

Is the platform safe for beginners?

Yes. Velnode provides a risk-free environment where learners can simulate high-voltage or high-pressure failures (like tank overflows) and master safety protocols without any physical danger or equipment damage.

How does the subscription model work?

We offer a flexible SaaS model: a "pay-as-you-use" subscription for individuals/students and enterprise licensing for institutions and corporate bodies, significantly reducing upfront CAPEX.

Is customisation of the lab models/simulation possible?

Yes. Through our Institutional Partnership model, we can work with technical training providers to align our simulation models with specific course outlines, ensuring that the virtual experiments directly support the training requirements.

Is there technical support available for users?

Yes. We provide dedicated technical support for both individual subscribers and partner institutions. This includes onboarding sessions for lecturers, troubleshooting for students, and regular updates to the simulation library to ensure the technology remains state-of-the-art.

Get started with Velnode today and spin up your first technical lab

Growth-Based Pricing

Expert Technical Support

No Hidden Costs